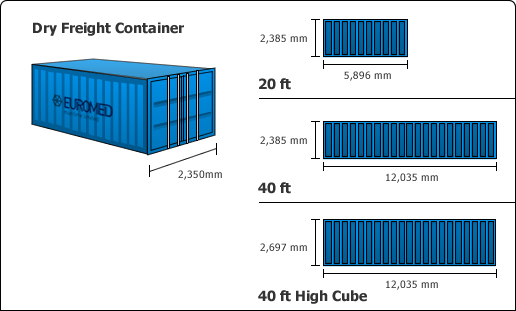

Specifications of containers:

Container Types

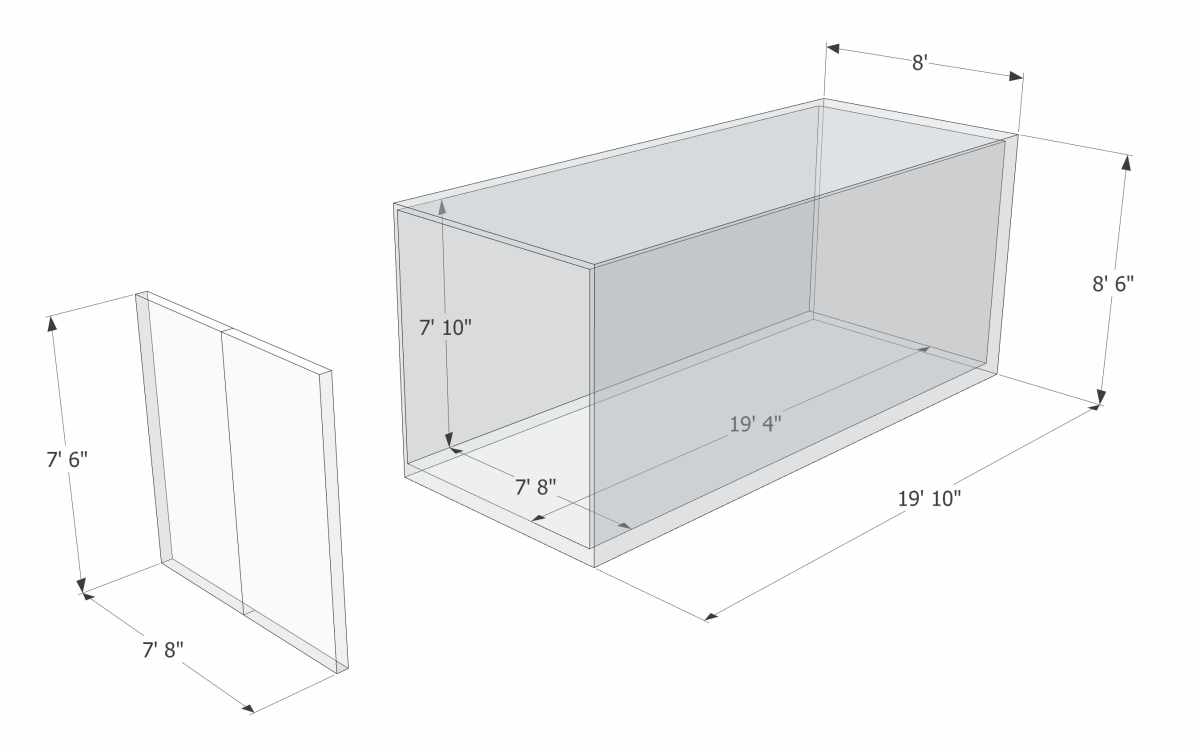

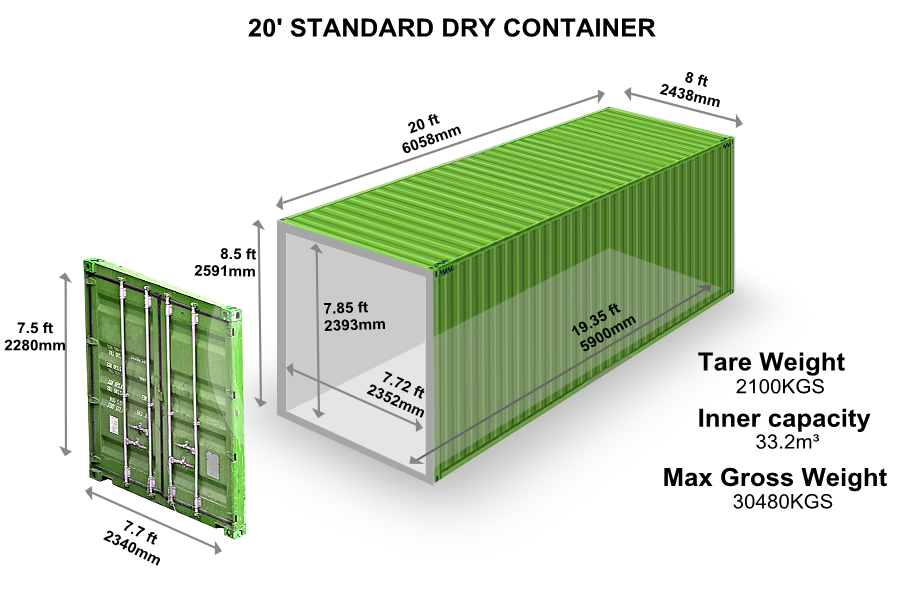

20' Standard:

| INSIDE LENGTH: | 5.895 m |

|---|---|

| INSIDE WIDTH: | 2.350 m |

| INSIDE HEIGHT: | 2.392 m |

| DOOR WIDTH: | 2.340 m |

| DOOR HEIGHT: | 2.292 m |

| CAPACITY: | 33 m3 |

| TARE WEIGHT: | 2230 Kgs |

| MAX CARGO WEIGHT: | 28230 Kgs |

Description

Standard containers are also known as general purpose containers

They are closed containers, i.e. they are closed on all sides. A distinction may be drawn between the following types of standard container:

- Standard containers with doors at one or both end(s)

- Standard containers with doors at one or both end(s) and doors over the entire length of one or both sides

- Standard containers with doors at one or both end(s) and doors on one or both sides

In addition, the various types of standard container also differ in dimensions and weight, resulting in a wide range of standard containers.

Standard containers are mainly used as 20' and 40' containers. Containers with smaller dimensions are very seldom used. Indeed, the trend is towards even longer dimensions, e.g. 45'.

Usage:

20' container has some advantages. It’s affordable compare to a longer container. It’s also easier to transport and move.

But the potential disadvantage is that it has a limited floor space.

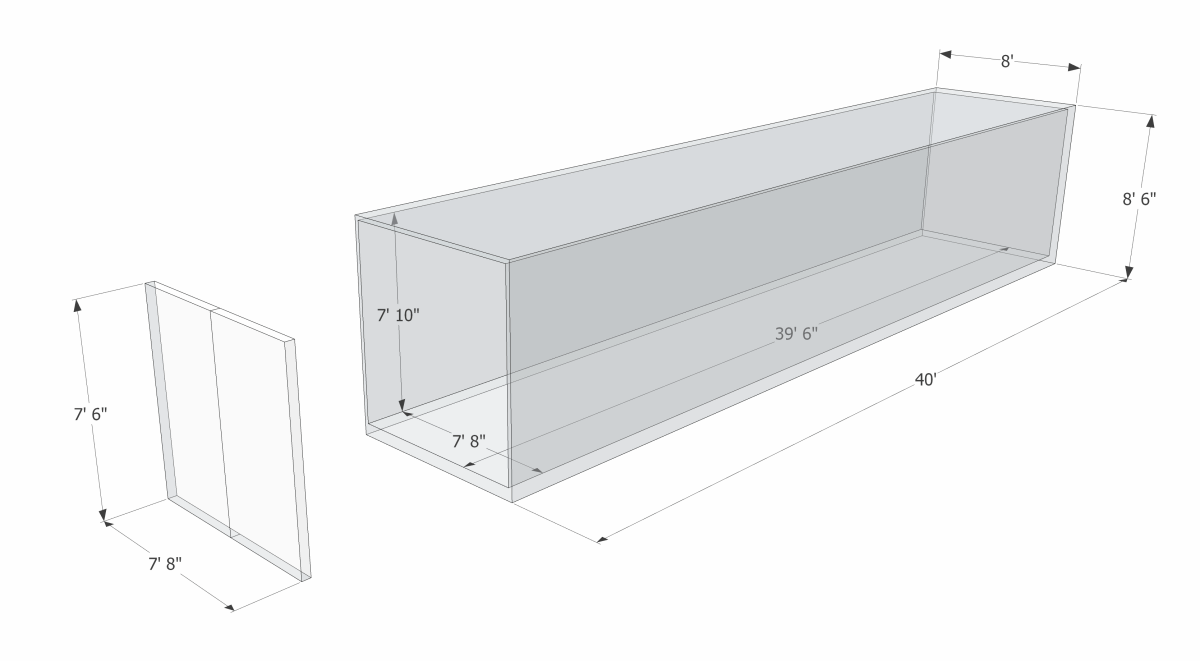

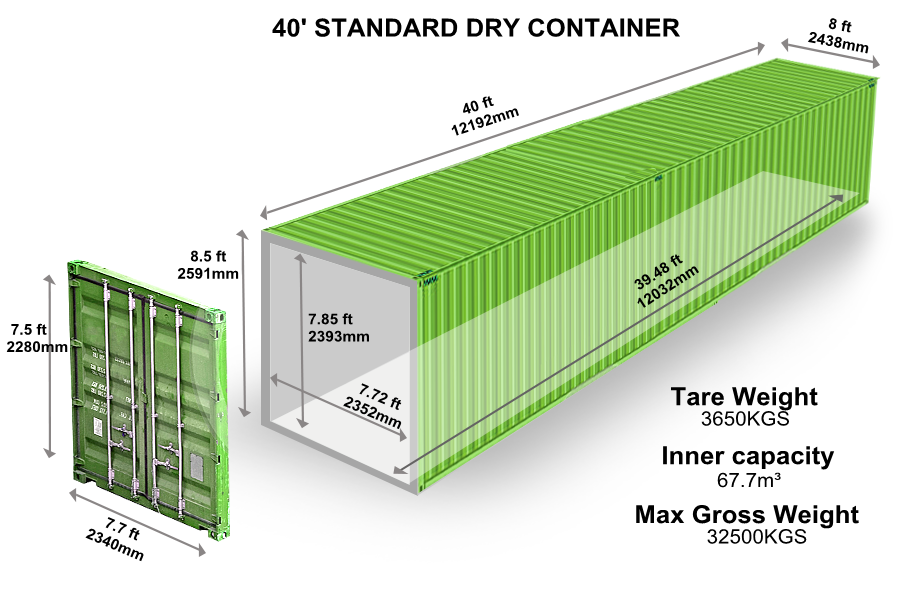

40' Standard:

| INSIDE LENGTH: | 12.029 m |

|---|---|

| INSIDE WIDTH: | 2.350 m |

| INSIDE HEIGHT: | 2.392 m |

| DOOR WIDTH: | 2.340 m |

| DOOR HEIGHT: | 2.292 m |

| CAPACITY: | 67 m3 |

| TARE WEIGHT: | 3780 Kgs |

| MAX CARGO WEIGHT: | 26700 Kgs |

Description

Standard containers are also known as general purpose containers.

They are closed containers, i.e. they are closed on all sides. A distinction may be drawn between the following types of standard container:

- Standard containers with doors at one or both end(s)

- Standard containers with doors at one or both end(s) and doors over the entire length of one or both sides

- Standard containers with doors at one or both end(s) and doors on one or both sides

In addition, the various types of standard container also differ in dimensions and weight, resulting in a wide range of standard containers.

Standard containers are mainly used as 20' and 40' containers. Containers with smaller dimensions are very seldom used. Indeed, the trend is towards even longer dimensions, e.g. 45'.

Usage:

Standard containers are used for all types general cargo (dry cargo).

40' High-Cube:

| INSIDE LENGTH: | 12.024 m |

|---|---|

| INSIDE WIDTH: | 2.350 m |

| INSIDE HEIGHT: | 2.697 m |

| DOOR WIDTH: | 2.340 m |

| DOOR HEIGHT: | 2.597 m |

| CAPACITY: | 76 m3 |

| TARE WEIGHT: | 4020 Kgs |

| MAX CARGO WEIGHT: | 26460 Kgs |

Description

High-cube containers are similar in structure to standard containers, but taller. In contrast to standard containers, which have a maximum height of 2591 mm (8'6"), high-cube containers are 2896 mm, or 9'6", tall. High-cube containers are for the most part 40' long, but are sometimes made as 45' containers.

A number of lashing rings, capable of bearing loads of at most 1000 kg, are mounted on the front top end rail and bottom cross member and the corner posts.

Many 40' containers have a recess in the floor at the front end which serves to center the containers on so-called gooseneck chassis. These recesses allow the containers to lie lower and therefore to be of taller construction.

Usage:

High-cube containers are used for all types general cargo (dry cargo). However, they are particularly suitable for transporting light, voluminous cargoes and overheight cargoes up to a maximum of 2.70 m tall.

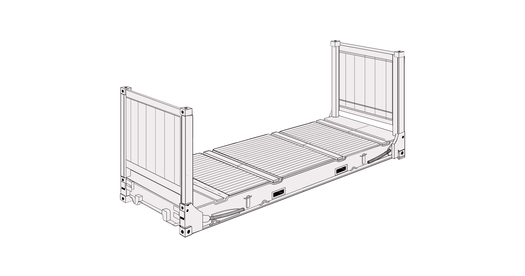

20' Flatrack:

| INSIDE LENGTH: | 5.698 m |

|---|---|

| INSIDE WIDTH: | 2.230 m |

| INSIDE HEIGHT: | 2.255 m |

| DOOR WIDTH: | - m |

| DOOR HEIGHT: | - m |

| CAPACITY: | - m3 |

| TARE WEIGHT: | 2500 Kgs |

| MAX CARGO WEIGHT: | 21500 Kgs |

Description

Flatracks consist of a floor structure with a high loading capacity composed of a steel frame and a softwood floor and two end walls, which may either be fixed or collapsible. The end walls are stable enough to allow cargo securing means to be attached and several flatracks to be stacked on top of one another. Flatracks are available in 20' and 40' sizes.

A number of lashing rings, to which the cargo may be secured, are installed in the side rails, the corner posts and the floor. The lashing rings may take loads of up to 2000 kg in the case of 20' flatracks or up to 4000 kg in the case of 40' flatracks.

Some types of 20' flatracks have forklift pockets.

40' flatracks have gooseneck tunnels at each end. In addition, they are sometimes equipped with lashing winches with 2 metric ton lashing belts.

For transport of certain cargoes, flatracks may be provided with stanchions.

Usage:

Flatracks are mainly used to transport heavy-lifts and over height or over width cargoes.

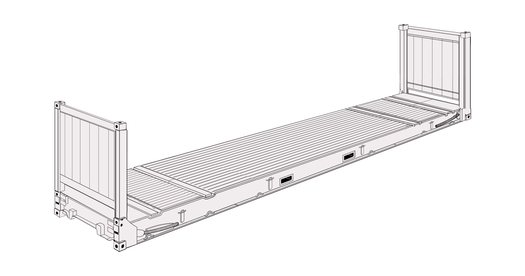

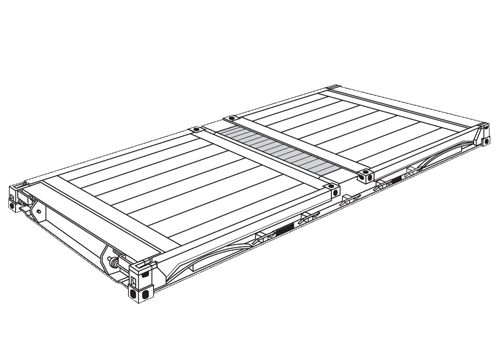

40' Flatrack:

| INSIDE LENGTH: | 11.832 m |

|---|---|

| INSIDE WIDTH: | 2.228 m |

| INSIDE HEIGHT: | 1.981 m |

| DOOR WIDTH: | - m |

| DOOR HEIGHT: | - m |

| CAPACITY: | - m3 |

| TARE WEIGHT: | 4200 Kgs |

| MAX CARGO WEIGHT: | 21500 Kgs |

Description

Flatracks consist of a floor structure with a high loading capacity composed of a steel frame and a softwood floor and two end walls, which may either be fixed or collapsible. The end walls are stable enough to allow cargo securing means to be attached and several flatracks to be stacked on top of one another. Flatracks are available in 20' and 40' sizes.

A number of lashing rings, to which the cargo may be secured, are installed in the side rails, the corner posts and the floor. The lashing rings may take loads of up to 2000 kg in the case of 20' flatracks or up to 4000 kg in the case of 40' flatracks.

Some types of 20' flatracks have forklift pockets.

40' flatracks have gooseneck tunnels at each end. In addition, they are sometimes equipped with lashing winches with 2 metric ton lashing belts.

For transport of certain cargoes, flatracks may be provided with stanchions.

Usage:

Flatracks are mainly used to transport heavy-lifts and over height or over width cargoes.

20' Opentop:

| INSIDE LENGTH: | 5.888 m |

|---|---|

| INSIDE WIDTH: | 2.345 m |

| INSIDE HEIGHT: | 2.315 m |

| DOOR WIDTH: | 2.286 m |

| DOOR HEIGHT: | 2.184 m |

| CAPACITY: | 32 m3 |

| TARE WEIGHT: | 2250 Kgs |

| MAX CARGO WEIGHT: | 30480 Kgs |

Description

The walls of open-top containers are generally made of corrugated steel. The floor is made of wood.

It has the following typical distinguishing structural features. The roof consists of removable bows and a removable tarpaulin. The door header may be swivelled out.

These two structural features greatly simplify the process of packing and unpacking the container. In particular, it is very easy to pack and unpack the container from above or through the doors by crane or crab when the roof is open and the door header is swivelled out.

It should be noted, however, that the purpose of the roof bows of an open-top container is not solely to support the tarpaulin but also to contribute to container stability. Flatracks are therefore more suitable for overheight cargoes.

Lashing rings, to which the cargo may be secured, are installed in the upper and lower side rails and the corner posts. The lashing rings may take loads of up to 1,000 kg.

Usual open-top container dimensions are 20' and 40'.

Usage:

Open-top containers are used for all types of general cargo (dry cargo). Their principal uses are as follows:

- packing and unpacking from above or through the doors by crane or crab

- tall cargo

40' Opentop:

| INSIDE LENGTH: | 12.029 m |

|---|---|

| INSIDE WIDTH: | 2.342 m |

| INSIDE HEIGHT: | 2.326 m |

| DOOR WIDTH: | 2.341 m |

| DOOR HEIGHT: | 2.274 m |

| CAPACITY: | 65 m3 |

| TARE WEIGHT: | 3810 Kgs |

| MAX CARGO WEIGHT: | 26670 Kgs |

Description

The walls of open-top containers are generally made of corrugated steel. The floor is made of wood.

It has the following typical distinguishing structural features. The roof consists of removable bows and a removable tarpaulin. The door header may be swivelled out.

These two structural features greatly simplify the process of packing and unpacking the container. In particular, it is very easy to pack and unpack the container from above or through the doors by crane or crab when the roof is open and the door header is swivelled out.

It should be noted, however, that the purpose of the roof bows of an open-top container is not solely to support the tarpaulin but also to contribute to container stability. Flatracks are therefore more suitable for overheight cargoes.

Lashing rings, to which the cargo may be secured, are installed in the upper and lower side rails and the corner posts. The lashing rings may take loads of up to 1,000 kg.

Usual open-top container dimensions are 20' and 40'.

Usage:

Open-top containers are used for all types of general cargo (dry cargo). Their principal uses are as follows:

- packing and unpacking from above or through the doors by crane or crab

- tall cargo

20' Platform:

| INSIDE LENGTH: | 6.058 m |

|---|---|

| INSIDE WIDTH: | 2.438 m |

| INSIDE HEIGHT: | 0.370 m |

| DOOR WIDTH: | - m |

| DOOR HEIGHT: | - m |

| CAPACITY: | - m3 |

| TARE WEIGHT: | 2520 Kgs |

| MAX CARGO WEIGHT: | 27960 Kgs |

Description

Platforms consist solely of a floor structure with extremely high loading capacity; they have no side or end walls. This high loading capacity makes it possible to concentrate heavy weights on small areas. A platform consists of a steel frame and a wooden floor structure.

Platforms are available in 20' and 40' sizes. 40' platforms have a gooseneck tunnel at each end.

Lashing rings, to which the cargo may be secured, are installed in the side rails. The lashing rings may take loads of up to 3.000 kg.

Usage:

Platforms are used principally for oversized and very heavy cargoes.

40' Platform:

| INSIDE LENGTH: | 12.192 m |

|---|---|

| INSIDE WIDTH: | 2.245 m |

| INSIDE HEIGHT: | 0.648 m |

| DOOR WIDTH: | - m |

| DOOR HEIGHT: | - m |

| CAPACITY: | - m3 |

| TARE WEIGHT: | 5700 Kgs |

| MAX CARGO WEIGHT: | 39300 Kgs |

Description

Platforms consist solely of a floor structure with extremely high loading capacity; they have no side or end walls. This high loading capacity makes it possible to concentrate heavy weights on small areas. A platform consists of a steel frame and a wooden floor structure.

Platforms are available in 20' and 40' sizes. 40' platforms have a gooseneck tunnel at each end.

Lashing rings, to which the cargo may be secured, are installed in the side rails. The lashing rings may take loads of up to 3.000 kg.

Usage:

Platforms are used principally for oversized and very heavy cargoes.

20' Refrigerated:

| INSIDE LENGTH: | 5.724 m |

|---|---|

| INSIDE WIDTH: | 2.286 m |

| INSIDE HEIGHT: | 2.014 m |

| DOOR WIDTH: | 2.286 m |

| DOOR HEIGHT: | 2.067 m |

| CAPACITY: | 26 m3 |

| TARE WEIGHT: | 2550 Kgs |

| MAX CARGO WEIGHT: | 21450 Kgs |

Description

The refrigeration unit is arranged in such a way that the external dimensions of the container meet ISO standards and thus fit into the container ship cell guides, for example. The presence of an integral refrigeration unit entails a loss of internal volume and payload.

When being transported by ship, integral units have to be connected to the on-board power supply system. The number of refrigerated containers which may be connected depends on the capacity of the ship's power supply system. If the aforesaid capacity is too low for the refrigerated containers to be transported, "power packs" may be used, which are equipped with relatively large diesel generators and satisfy ISO requirements with regard to the dimensions of a 20' container. When at the terminal, the containers are connected to the terminal's power supply system. For transport by road and rail, most integral unit refrigeration units are operated by a generator set (genset). This may either be a component of the refrigeration unit or connected to the refrigeration unit.

Air flows through the container from bottom to top. In general, the "warm" air is drawn off from the inside of the container, cooled in the refrigeration unit and then blown back in the container as cold air.

To ensure adequate circulation of the cold air, the floor is provided with gratings. Pallets form an additional space between container floor and cargo, so also forming a satisfactory air flow channel. In addition, the side walls of the container are "corrugated", which ensures satisfactory air flow there too.

In the upper area of the container, adequate space (at least 12 cm) must likewise be provided for air flow. For this purpose, during packing of the container adequate free space must be left above the cargo. The maximum load height is marked on the side walls.

To ensure vertical air flow from bottom to top, packaging must also be appropriately designed and the cargo must be sensibly stowed.

In addition to temperature regulation, integral units also allow a controlled fresh air exchange, for example for the removal of metabolic products such as CO2 and ethylene in the case of the transport of fruits.

In the refrigeration units, both the supply and return air temperatures are measured and, depending on the operating mode, one of these values is used to control the cold air. Temperature measurement may be performed in various ways. The Partlow recorder generally records return air temperature, since this provides an indication of the state or temperature of the cargo. Data loggers are increasingly used, which detect temperature digitally and indicate it on a display. Once transferred to a PC, the data may then be evaluated.

The temperature display is attached to the outside of the refrigeration unit, so that operation of the unit may be checked at any time.

Digital or analog recorders may also be positioned directly in the cargo, so as to measure temperatures inside the container. The recorder should be accommodated in such a way that it records the temperatures at risk points in the container (inside the packaging, top layer at door end).

Integral units may be stowed both above and below deck on a ship. Above deck stowage has the advantage that the heat from return air may be more readily dissipated. However, the containers are often exposed to strong solar radiation, leading to increased refrigeration capacity requirements.

Usage:

Refrigerated containers are used for goods which need to be transported at a constant temperature above or below freezing point. These goods are divided into chilled goods and frozen goods, depending on the specified transport temperature. They principally include fruit, vegetables, meat and dairy products, such as butter and cheese.

High-cube integral units are used in particular for voluminous and light goods (e.g. fruit, flowers).

Nowadays, goods requiring refrigeration are mostly transported in integral units, which have a markedly higher market share than porthole containers.

Chilled meat is sometimes also transported hanging, for which purpose the ceilings of refrigerated containers are equipped with special hook rails.

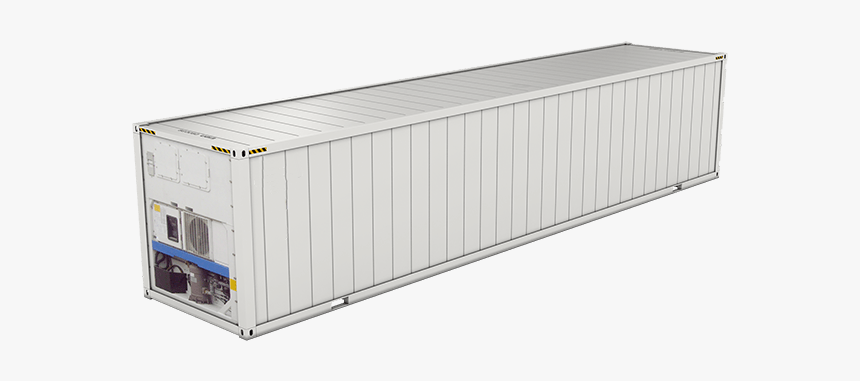

40' Opentop:

| INSIDE LENGTH: | 11.840 m |

|---|---|

| INSIDE WIDTH: | 2.286 m |

| INSIDE HEIGHT: | 2.120 m |

| DOOR WIDTH: | 2.286 m |

| DOOR HEIGHT: | 2.195 m |

| CAPACITY: | 60 m3 |

| TARE WEIGHT: | 3850 Kgs |

| MAX CARGO WEIGHT: | 26630 Kgs |

Description

The refrigeration unit is arranged in such a way that the external dimensions of the container meet ISO standards and thus fit into the container ship cell guides, for example. The presence of an integral refrigeration unit entails a loss of internal volume and payload.

When being transported by ship, integral units have to be connected to the on-board power supply system. The number of refrigerated containers which may be connected depends on the capacity of the ship's power supply system. If the aforesaid capacity is too low for the refrigerated containers to be transported, "power packs" may be used, which are equipped with relatively large diesel generators and satisfy ISO requirements with regard to the dimensions of a 20' container. When at the terminal, the containers are connected to the terminal's power supply system. For transport by road and rail, most integral unit refrigeration units are operated by a generator set (genset). This may either be a component of the refrigeration unit or connected to the refrigeration unit.

Air flows through the container from bottom to top. In general, the "warm" air is drawn off from the inside of the container, cooled in the refrigeration unit and then blown back in the container as cold air.

To ensure adequate circulation of the cold air, the floor is provided with gratings. Pallets form an additional space between container floor and cargo, so also forming a satisfactory air flow channel. In addition, the side walls of the container are "corrugated", which ensures satisfactory air flow there too.

In the upper area of the container, adequate space (at least 12 cm) must likewise be provided for air flow. For this purpose, during packing of the container adequate free space must be left above the cargo. The maximum load height is marked on the side walls.

To ensure vertical air flow from bottom to top, packaging must also be appropriately designed and the cargo must be sensibly stowed.

In addition to temperature regulation, integral units also allow a controlled fresh air exchange, for example for the removal of metabolic products such as CO2 and ethylene in the case of the transport of fruits.

In the refrigeration units, both the supply and return air temperatures are measured and, depending on the operating mode, one of these values is used to control the cold air. Temperature measurement may be performed in various ways. The Partlow recorder generally records return air temperature, since this provides an indication of the state or temperature of the cargo. Data loggers are increasingly used, which detect temperature digitally and indicate it on a display. Once transferred to a PC, the data may then be evaluated.

The temperature display is attached to the outside of the refrigeration unit, so that operation of the unit may be checked at any time.

Digital or analog recorders may also be positioned directly in the cargo, so as to measure temperatures inside the container. The recorder should be accommodated in such a way that it records the temperatures at risk points in the container (inside the packaging, top layer at door end).

Integral units may be stowed both above and below deck on a ship. Above deck stowage has the advantage that the heat from return air may be more readily dissipated. However, the containers are often exposed to strong solar radiation, leading to increased refrigeration capacity requirements.

Usage:

Refrigerated containers are used for goods which need to be transported at a constant temperature above or below freezing point. These goods are divided into chilled goods and frozen goods, depending on the specified transport temperature. They principally include fruit, vegetables, meat and dairy products, such as butter and cheese.

High-cube integral units are used in particular for voluminous and light goods (e.g. fruit, flowers).

Nowadays, goods requiring refrigeration are mostly transported in integral units, which have a markedly higher market share than porthole containers.

Chilled meat is sometimes also transported hanging, for which purpose the ceilings of refrigerated containers are equipped with special hook rails.

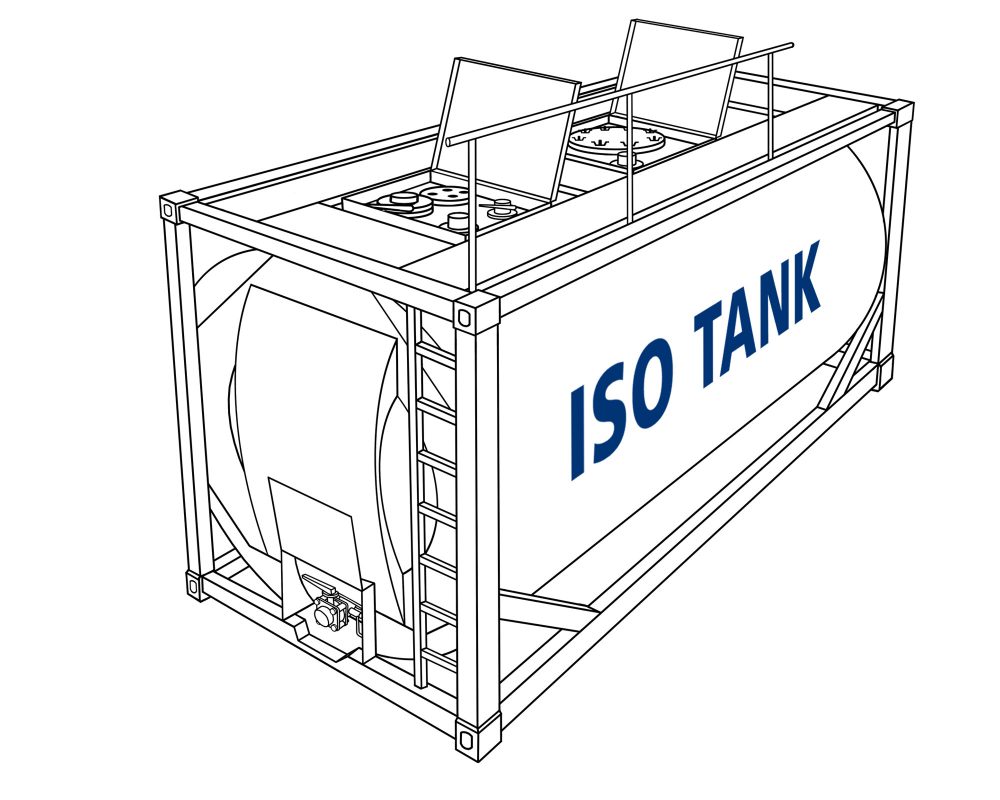

20' Isotank:

| INSIDE LENGTH: | 6.058 m |

|---|---|

| INSIDE WIDTH: | 2.438 m |

| INSIDE HEIGHT: | 2.438 m |

| DOOR WIDTH: | - m |

| DOOR HEIGHT: | - m |

| CAPACITY: | - m3 |

| TARE WEIGHT: | 4190 Kgs |

| MAX CARGO WEIGHT: | 27960 Kgs |

Description

Tank containers must be at least 80%% full, to prevent dangerous surging of the liquids in transit. On the other hand, they must not as a rule be over 95%% full, or there will not be sufficient ullage space for thermal expansion. The extent of thermal expansion may be calculated for each cargo on the basis of the following formula:

- ΔV = Va · γ · ΔT

- Ve = Va (1 γ · ΔT)

- ΔV : change in volume

- Va : volume at initial temperature a

- Ve : final volume at temperature e

- γ : coefficient of cubic (thermal) expansion

- ΔT : temperature difference in degrees kelvin

Tank containers intended for transporting foodstuffs must be labeled "Potable Liquids only".

Some hazardous materials must be transported in tank containers with no in- or outlet openings below the surface of the liquid.

Tank containers are generally designed for an operating pressure of up to 3 bar (above atmospheric). The test pressure used is 4.5 bar (above atmospheric).

If the cargo requires temperature-controlled transport, tank containers can be equipped with insulation or heating. The temperature of the cargo may be precisely controlled using temperature sensors.

Usage:

Tank containers are used for liquid cargoes, such as:

- Foodstuffs: fruit juices, spirits, sweet oils

- Chemicals: hazardous materials, such as fuels, toxic substances, corrosion protection agents

Fresh Fruits and Vegetables

Request a Price

Chilled and Frozen Foods

Request a Price

Other Foods

Request a Price

Railway wagon types:

Wagon Types

Coverd Wagons

Four-axle covered wagon with metal front wall

| Loading capacity: | 66 ton |

|---|---|

| Tare weight: | 23 ton |

| Volume: | 120 m3 |

Four-axle covered wagon with broadened doorways

| Loading capacity: | 68 ton |

|---|---|

| Tare weight: | 22 ton |

| Volume: | 120 m3 |

Four-axle covered wagon

| Loading capacity: | 50 ton |

|---|---|

| Tare weight: | 35 ton |

| Volume: | 120 m3 |

Four-axle covered 2-storied livestock wagon

| Loading capacity: | 22 ton |

|---|---|

| Tare weight: | 25.4 ton |

Four-axle covered all-metal wagon for automobiles

| Loading capacity: | 42 ton |

|---|---|

| Tare weight: | 42 ton |

Four-axle hopper wagon for cement

| Loading capacity: | 67 ton |

|---|---|

| Tare weight: | 18.5 ton |

| Volume: | 55 m3 |

Four-axle covered hopper/wagon for mineral fertilizers

| Loading capacity: | 64 ton |

|---|---|

| Tare weight: | 22 ton |

| Volume: | 73 m3 |

Four-axle wagon for granular polymer

| Loading capacity: | 60 ton |

|---|---|

| Tare weight: | 24 ton |

| Volume: | 130 m3 |

Open Wagons

Six-axle all-metal open wagon

| Loading capacity: | 94 ton |

|---|---|

| Tare weight: | 31 ton |

| Volume: | 104 m3 |

Four-axle all-metal open wagon

| Loading capacity: | 69 ton |

|---|---|

| Tare weight: | 22 ton |

| Volume: | 73 m3 |

Four-axle open wagon

| Loading capacity: | 69 ton |

|---|---|

| Tare weight: | 22.5 ton |

| Volume: | 74 m3 |

Four–axle wagon for containers of middle tonnage on open wagon base

| Loading capacity: | 23 ton |

|---|---|

| Tare weight: | 21 ton |

Four–axle all-metal wagon for pulpchips

| Loading capacity: | 58 ton |

|---|---|

| Tare weight: | 25.85 ton |

| Volume: | 135 m3 |

Four–axle open hopper- for hot pellet

| Loading capacity: | 65 ton |

|---|---|

| Tare weight: | 23 ton |

| Volume: | 42 m3 |

Flat Wagons

Eight-axle open wagon

| Loading capacity: | 70 ton |

|---|---|

| Tare weight: | 29.9 ton |

Four-axle all-metal open wagon

| Loading capacity: | 56 ton |

|---|---|

| Tare weight: | 34 ton |

Four-axle open wagon

| Loading capacity: | 73 ton |

|---|---|

| Tare weight: | 27 ton |

Four–axle wagon for containers of middle tonnage on open wagon base

| Loading capacity: | 70 ton |

|---|---|

| Tare weight: | 24 ton |

Tank Wagons

Eight-axle tank wagon for oil products

| Loading capacity: | 120 ton |

|---|---|

| Tare weight: | 48.8 ton |

| Volume: | 140 m3 |

Four-axle tank wagon for petrol and light oil

| Loading capacity: | 62 ton |

|---|---|

| Tare weight: | 23.5 ton |

| Volume: | 88.6 m3 |

Four-axle tank wagon for tough oil product

| Loading capacity: | 63.5 ton |

|---|---|

| Tare weight: | 24.23 ton |

| Volume: | 73.1 m3 |

Four-axle tank wagon for hydrochloric acid

| Loading capacity: | 62 ton |

|---|---|

| Tare weight: | 22.5 ton |

| Volume: | 54.06 m3 |

Four-axle tank wagon for phenol

| Loading capacity: | 62 ton |

|---|---|

| Tare weight: | 23.4 ton |

| Volume: | 62.39 m3 |

Four-axle tank wagon for propane

| Loading capacity: | 22.9 ton |

|---|---|

| Tare weight: | 35.2 ton |

| Volume: | 54 m3 |

Four-axle tank wagon for propane

| Loading capacity: | 22.9 ton |

|---|---|

| Tare weight: | 35.2 ton |

| Volume: | 54 m3 |

Four-axle tank wagon for chlorine

| Loading capacity: | 57.5 ton |

|---|---|

| Tare weight: | 29.4 ton |

| Volume: | 46 m3 |

Four-axle tank wagon for soda ash

| Loading capacity: | 54 ton |

|---|---|

| Tare weight: | 31.3 ton |

| Volume: | 101.57 m3 |

Four-axle tank wagon for spirit

| Loading capacity: | 59 ton |

|---|---|

| Tare weight: | 23.2 ton |

| Volume: | 73.1 m3 |

Four-axle tank wagon for molten sulfur

| Loading capacity: | 62 ton |

|---|---|

| Tare weight: | 25.8 ton |

| Volume: | 38.5 m3 |

Four-axle tank wagon for liquid pitch

| Loading capacity: | 60 ton |

|---|---|

| Tare weight: | 27.5 ton |

| Volume: | 54.4 m3 |

Four-axle tank wagon for naphthalene

| Loading capacity: | 50.8 ton |

|---|---|

| Tare weight: | 28.3 ton |

| Volume: | 52.5 m3 |

Four-axle tank wagon for vinyl chloride

| Loading capacity: | 58.4 ton |

|---|---|

| Tare weight: | 28.8 ton |

| Volume: | 73 m3 |

Four-axle tank wagon for liquefied hydrocarbon gases

| Loading capacity: | 31 ton |

|---|---|

| Tare weight: | 36 ton |

| Volume: | 50 m3 |

Tank Wagons

Eight-axle tank wagon for oil products

| Loading capacity: | 120 ton |

|---|---|

| Tare weight: | 48.8 ton |

| Volume: | 140 m3 |

Four-axle tank wagon for petrol and light oil

| Loading capacity: | 62 ton |

|---|---|

| Tare weight: | 23.5 ton |

| Volume: | 88.6 m3 |

Four-axle tank wagon for tough oil product

| Loading capacity: | 63.5 ton |

|---|---|

| Tare weight: | 24.23 ton |

| Volume: | 73.1 m3 |

Four-axle tank wagon for hydrochloric acid

| Loading capacity: | 62 ton |

|---|---|

| Tare weight: | 22.5 ton |

| Volume: | 54.06 m3 |

Four-axle tank wagon for phenol

| Loading capacity: | 62 ton |

|---|---|

| Tare weight: | 23.4 ton |

| Volume: | 62.39 m3 |

Four-axle tank wagon for propane

| Loading capacity: | 22.9 ton |

|---|---|

| Tare weight: | 35.2 ton |

| Volume: | 54 m3 |

Four-axle tank wagon for propane

| Loading capacity: | 22.9 ton |

|---|---|

| Tare weight: | 35.2 ton |

| Volume: | 54 m3 |

Four-axle tank wagon for chlorine

| Loading capacity: | 57.5 ton |

|---|---|

| Tare weight: | 29.4 ton |

| Volume: | 46 m3 |

Four-axle tank wagon for soda ash

| Loading capacity: | 54 ton |

|---|---|

| Tare weight: | 31.3 ton |

| Volume: | 101.57 m3 |

Four-axle tank wagon for spirit

| Loading capacity: | 59 ton |

|---|---|

| Tare weight: | 23.2 ton |

| Volume: | 73.1 m3 |

Four-axle tank wagon for molten sulfur

| Loading capacity: | 62 ton |

|---|---|

| Tare weight: | 25.8 ton |

| Volume: | 38.5 m3 |

Four-axle tank wagon for liquid pitch

| Loading capacity: | 60 ton |

|---|---|

| Tare weight: | 27.5 ton |

| Volume: | 54.4 m3 |

Four-axle tank wagon for naphthalene

| Loading capacity: | 50.8 ton |

|---|---|

| Tare weight: | 28.3 ton |

| Volume: | 52.5 m3 |

Four-axle tank wagon for vinyl chloride

| Loading capacity: | 58.4 ton |

|---|---|

| Tare weight: | 28.8 ton |

| Volume: | 73 m3 |

Four-axle tank wagon for liquefied hydrocarbon gases

| Loading capacity: | 31 ton |

|---|---|

| Tare weight: | 36 ton |

| Volume: | 50 m3 |

Dump and Oil Products Wagons

Four-axle flat wagon for bitumen

| Loading capacity: | 40 ton |

|---|---|

| Tare weight: | 32.25 ton |

| Volume: | 47.2 ton |

Six-axle dump car

| Loading capacity: | 105 ton |

|---|---|

| Tare weight: | 48.5 ton |

| Volume: | 50 ton |

High-capacity Wagons

Flat wagon, model Laas

| Loading capacity: | 54 ton |

|---|---|

| Tare weight: | 26 ton |

Flat wagon, model Laaps

| Loading capacity: | 55 ton |

|---|---|

| Tare weight: | 25 ton |

Flat wagon, model TWA 850 (RV)

| Loading capacity: | 44 / 36 ton |

|---|---|

| Tare weight: | 28 ton |

Four-axle wagon, model Habis-2

| Loading capacity: | 51 ton |

|---|---|

| Tare weight: | 29 ton |

| Volume: | 163 m3 |

Four-axle wagon, model Habbins-15

| Loading capacity: | 56 / 64 ton |

|---|---|

| Tare weight: | 26 ton |

| Volume: | 167 m3 |

Four-axle wagon, model Habbins-14

| Loading capacity: | 54 / 62 ton |

|---|---|

| Tare weight: | 27.5 ton |

| Volume: | 180 m3 |

Four-axle wagon, model Sins

| Loading capacity: | 54 / 62 ton |

|---|---|

| Tare weight: | 28 ton |

| Volume: | 166 m3 |

Four-axle wagon, model Hirrs (HRP)

| Loading capacity: | 46.5 ton |

|---|---|

| Tare weight: | 33.5 ton |

| Volume: | 2x105 m3 |

Four-axle wagon, model Laakklps

| Loading capacity: | 47 ton |

|---|---|

| Tare weight: | 33 ton |

| Volume: | 2x85.5 m3 |

Pallets Dimensions

A pallet is a flat, often wooden structure that is used to handle transport, storing goods, or shipping freight. More details about types of pallets, materials, and measurements are illustrated here under.

Dimensions

W x L inch

Dimensions

W x L mm

Unused floor space

in40’ Container

Region

Most used in

40 X 48

800 X 1200

3.7 %

North America

39.37 X 47.24

1000 X 1200

6.7 %

Europe, Asia

similar to 40” x 4”

45.9 x 45.9

1165 x 1165

8.1 %

Australia

42 X 42

1067 X 1067

11.5 %

North America,

Europe, Asia

43.3 X 43.3

1100 X 1100

14 %

Asia

31.5 x 47.24

31.5 x 47.24

15.2 %

Europe

Type

Dimensions

W x L X D inch

Dimensions

W x L x D mm

ISO

Alternative

EUR &

EUR 1

31.50 x 47.24 x 5.71

800 x 1200 x 145

Same sizes are EUR & EUR1.

Pallet weight: 20-25 kg.

Load weight: 2490 kg.

EUR 2

47.24 x 39.37 x 5.67

1200 x 1000 x 144

ISO, 33 kg

Load weight: 1470 kg.

EUR 3

31.50 x 47.24 x 5.67

1000 x 1200 x 144

Pallet weight: 29 kg.

Load weight: 1920 kg.

EUR 6

31.50 x 23.62 x 5.67

800 x 600 x 144

Iso, half size of EUR.

Pallet weight: 9.5 kg.

Safe load weight: 500 kg.

Dimensions

W x L inch

Dimensions

W x L mm

Proguction rank

Industries using

Most used in

40 X 48

1016 X 1219

1

Grocery, many others

42 X 42

1067 X 1067

2

Telecommunications, Paint

48 x 48

1219 x 1219

3

Drums

48 X 42

1219 X 1067

4

Military, Cement

40 X 40

1016 X 1016

6

Dairy

48 x 45

1219 x 1143

7

Automotive

44 x 44

1118 x 1118

8

Drums, Chemical

36 x 36

914 x 914

9

Beverage

48 x 36

1219 x 914

10

Beverage, Shingles, Packaget Paper

35 x 45.5

889 x 1156

Unknown

Military 1/2 ISO Container, fits 36” Standart Doors

48 x 20

1219 x 508

Unknown

Retail

Dimensions

W x L inch

Dimensions

W x L mm

Used in

45.87 X 45.87

11.65 x 11.65

Storage & Warehousing

Euro pallets 1200mm x 800mm

Container 40' standard

25 pallets

21 pallets

Container 40' palletwide 2.5m

25 pallets

24 pallets

Container 45' standard

27 pallets

25 pallets

Container 45' palletwide 2.5m

33 pallets

26 pallets

Incoterms

An illustration to the Incoterms is provided here under.

Incoterms published by the International Chamber of Commerce (ICC)

Incoterms 2020

EXW – Ex Works (named place)

The meaning of it is that the recipient takes the goods from the premises of the supplier, it can be a store, warehouse, etc. The supplier does not bear any obligations, except for the shipment of goods. All costs are borne by the recipient. EXW is not intended for the transport of goods to the EU. EXW is not used if the recipient is not able to export independently. EXW is for domestic traffic. EXW condition is used to transport goods by any means of transport.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

FCA - Free Carrier (named place of origin)

The most common term (almost 40% of international treaties are drawn up with this rule), because it is universal and easy to use. The best benefits are the use of any type of transport and any place of delivery of goods that is located in the seller’s country. There are 2 points of dispatch:

1. A point of dispatch of goods that belongs to the seller - this can be his warehouse, store, etc. Delivery is considered completed if the goods are loaded on the buyer's vehicle or transferred to the courier specified by the buyer.

2. A point that does not belong to the seller - it can be a seaport, airport, etc. Delivery is considered completed when the goods have been transferred to the carrier from the seller’s vehicle. Unloading goods from the seller’s vehicle is not the responsibility of the carrier.

If the buyer instructed to give the seller a package of documents (for example, a bill of lading marked “on board” or an air waybill) then the carrier must provide all original consignment notes to the seller.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

FAS – Free Alongside Ship

The meaning of it is that the delivery is completed for the supplier when the product is on the quay for loading on vessel hired by the recipient. FAS is intended only for transporting goods by sea or inland waterway. Supplier pays the export duty, packaging of goods and transportation of cargo to the port, as well as the possible costs of arrival at the port, and provides the relevant documentation. Recipient loads the goods onto the ship, hires and pays the ship, bears all the costs of transporting the goods to the destination, insures the goods, pays import duty, relevant certificates, licenses, etc. FAS is designed to transport goods in bulk or in containers, and also for transportation of heavy equipment.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

FOB - Free On Board (named port of loading)

The meaning of it is that the delivery is completed for the supplier when the product is on board the ship hired by the recipient. FOB is intended only for transporting goods by sea or inland waterway. The responsibilities of the supplier and the recipient are shared equally. Supplier pays export duty, packaging the goods and transportation of the cargo to the port, loads the goods on board and provides the relevant documentation. Recipient hires and pays the ship, insures the goods, pays import duty, relevant certificates, licenses, etc. FOB is designed to transport goods in bulk or in containers, and also for transportation of heavy equipment.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

CFR/C&F - Cost and Freight (named port of destination)

The meaning of it is that the delivery is completed for the supplier when the product is on board the ship hired by the supplier to a port of destination. CFR is intended only for transporting goods by sea or inland waterway. Supplier pays export duty, packaging the goods and transportation of the cargo to the port, loads the goods on board, hires and pays the ship and provides the relevant documentation. Recipient unloads the vessel, delivers the goods to the destination, insures the goods, pays import duty, relevant certificates, licenses, etc. CFR is designed to transport goods in bulk or in containers, and also for transportation of heavy equipment.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

CIF - Cost, Insurance and Freight (named port of destination)

The meaning of it is that the delivery is completed for the supplier when the product came on board the vessel, products have been insured by the supplier, and the vessel was hired by him to transport the goods to the destination port, which is established in the agreement. CIF is intended only for transporting goods by sea or inland waterway. Supplier pays export duty, packaging the goods and transportation of the cargo to the port, loads the goods on board, hires and pays the ship, insures the goods and provides the relevant documentation. Recipient unloads the vessel, pays import duty, relevant certificates, licenses, etc., delivers the goods to the point set in the agreement. CIF is designed to transport goods in bulk or in containers, and also for transportation of heavy equipment.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

CIF - Cost, Insurance and Freight (named port of destination)

The meaning of it is that the delivery is completed for the supplier when the product came on board the vessel, products have been insured by the supplier, and the vessel was hired by him to transport the goods to the destination port, which is established in the agreement. CIF is intended only for transporting goods by sea or inland waterway. Supplier pays export duty, packaging the goods and transportation of the cargo to the port, loads the goods on board, hires and pays the ship, insures the goods and provides the relevant documentation. Recipient unloads the vessel, pays import duty, relevant certificates, licenses, etc., delivers the goods to the point set in the agreement. CIF is designed to transport goods in bulk or in containers, and also for transportation of heavy equipment.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

DAP - Delivered at Place

The meaning of it is that the delivery is completed for the supplier when the goods are delivered to the recipient and ready for unloading at the indicated destination. Supplier must pay all export duties and costs for the delivery of the goods to the specified destination, its unloading. Supplier pays export duty, packaging the goods and transportation of the cargo to the port, loads the goods on board, hires and pays the ship, provides the relevant documentation, and also pays for unloading from the ship and delivery to the final destination. Recipient unloads a vehicle on spot, insures the goods at will, pays import duty, relevant certificates, licenses, etc. DAP is used to transport goods by any means of transport.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

DPU - Delivered Named Place Unloaded

The meaning of it is that the delivery is completed for the supplier when the goods are placed at the disposal of the recipient at the indicated place. Supplier must bear all costs for export duties and delivery of goods to the specified destination, including its unloading. Supplier pays for export duty, packaging the goods and transportation of the cargo to the port, loads the products on board, hires and pays the ship, engages in unloading from a ship, and optionally delivers and unloads at the destination. Recipient insures the goods at will, pays import duty, relevant certificates, licenses, etc. DPU is used to transport goods by any means of transport.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

DDP - Delivered Duty Paid

The meaning of it is that the delivery is completed for the supplier when the goods are delivered to the recipient, import duty paid and cargo ready for unloading at the indicated destination. DDP clause implies maximum obligations for the shipper, as opposed to EXW clause, where all shipping responsibilities are placed on the recipient. Recipient assumes only the unloading of goods on the spot and insurance of the goods at will. All other costs are transferred to the supplier (export and import payments, costs of transportation of goods) DDP is used to transport goods by any means of transport.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

Expected changes

CNI - Cost and Insurance

The term means that delivery is completed for the supplier, if the goods are insured, placed at the indicated port of shipment This term is included in category “C” and means that all duties for the safety of the goods are transferred at the point of departure from the supplier to the recipient. Also, this concept will allow the supplier-exporter to be responsible for the international insurance coverage of the goods. CNI contract terms include the cost of international insurance coverage at the expense of the supplier, and does not include freight (difference between CNI and CRF/CIF). The term is intended to eliminate all inaccuracies between the terms FCA and CFR / CIF.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

Incoterms 2010

DAT - Delivered at Terminal (...named terminal at port or place of destination)

The meaning of it is that the procurement is completed for the supplier when the loads are available to the recipient at the destination terminal. Supplier must bear all costs for export duties and supply of cargo to the specified destination, including its unloading. Supplier pays for export duty, packaging the goods and transportation of the goods to the port, loads the products on board, hires and pays the ship, engages in unloading from a vessel. Recipient insures the cargo at will, pays delivery to destination, import duty, unloading, relevant certificates, licenses, etc. DAT is used to transport cargo by any means of transport.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

Incoterms 2000

DDU - Delivered Duty Unpaid (named place of destination)

The meaning of it is that the delivery is completed for the supplier when the goods are delivered to the recipient at the indicated destination. Supplier must pay all export duties and costs for the delivery of the goods to the specified destination. Supplier pays export duty, packaging the goods and transportation of the cargo to the port, loads the goods on board, hires and pays the ship, provides the relevant documentation, and also pays for delivery to the final destination. Recipient insures the goods at will, pays import duty, relevant certificates, licenses, etc. and unloads a vehicle on spot. DDU is used to transport goods by any means of transport.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

DES - Delivered Ex Ship (named port of destination)

The meaning of it is that the delivery is completed for the supplier when the goods are delivered to the recipient at the indicated port of destination. Supplier must pay all export duties and costs for the delivery of the goods to the specified destination. DES is intended only for transporting goods by sea or inland waterway. Supplier pays export duty, packaging the goods and transportation of the cargo to the port, loads the goods on board, hires and pays the ship, engages in unloading from a ship. Recipient insures the goods at will, arranges last mile delivery, pays import duty, relevant certificates, licenses, etc. and unloads a vehicle on spot. DES is designed to transport goods in bulk or in containers, and also for transportation of heavy equipment.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

DEQ - Delivered Ex Quay (named port of destination)

The meaning of it is that the delivery is completed for the supplier when the goods are placed at the disposal of the recipient at the indicated port. DEQ is intended only for transporting goods by sea or inland waterway. Supplier must bear all costs for export duties and delivery of goods to the specified destination, including its unloading. Supplier pays for export duty, packaging the goods and transportation of the cargo to the port, loads the products on board, hires and pays the ship, engages in unloading from a ship and covers port fees to bring the cargo ex quay. Recipient insures the goods at will, pays import duty, relevant certificates, licenses, etc., delivers and unloads cargo at destination. DEQ is designed to transport goods in containers, and also for transportation of heavy equipment.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

DAF - Delivered At Frontier (named place)

The meaning of it is that the delivery is completed for the supplier when the goods are delivered to the recipient at the specified location on the border. Supplier must pay all export duties and costs for the delivery of the goods to the specified destination. Supplier pays export duty, packaging the goods and transportation of the cargo to the port, loads the goods on board, hires and pays the ship, for unloading from the ship and delivery to the named place on border, provides the relevant documentation. Recipient arranges last mile delivery, insures the goods at will, pays import duty, relevant certificates, licenses, etc. and unloads a vehicle on spot DAF is used to transport goods by any means of transport.

Who covers the logistics charges?

Distribution of costs according to the Incoterm negotiated in the contract. Classification according to the increased level of obligations for the seller.

IMO Classes

for Dangerous Goods

The Carriage of dangerous goods and marine pollutants in sea-going ships is respectively regulated in the International Convention for the Safety of the Life at Sea (SOLAS) and the International Convention for the Prevention of pollution from Ships (MARPOL).

Relevant parts of both SOLAS and MARPOL have been worked out in great detail and are included in the International Maritime Dangerous Goods (IMDG) Code, thus making this Code the legal instrument for maritime transport of dangerous goods and marine pollutants. As of 1st January 2004, the IMDG Code will become a mandatory requirement.

Classification of dangerous goods

For all modes of transport (sea, air, rail, road and inland waterways) the classification (grouping) of dangerous goods, by type of risk involved, has been drawn up by the UNITED NATIONS Committee of Experts on the Transport of Dangerous Goods (UN).

Class 1: Explosives

Subclass 1.1

Consists of explosives that have a mass explosion hazard. A mass explosion is one which affects almost the entire load instantaneously.

Subclass 1.2

Consists of explosives that have a projection hazard but not a mass explosion hazard.

Subclass 1.3

Consists of explosives that have a fire hazard and either a minor blast hazard or a minor projection hazard or, both but not a mass explosion hazard.

Subclass 1.4

Consists of explosives that present a minor explosion hazard. The explosive effects are largely confined to the package and no projection of fragments of appreciable size or range is to be expected. An external fire must not cause virtually instantaneous explosion of almost the entire contents of the package.

Subclass 1.5

Consists of very insensitive explosives. This division is comprised of substances which have a mass explosion hazard but are so insensitive that there is very little probability of initiation or of transition from burning to detonation under normal conditions of transport.

Subclass 1.6

Consists of extremely insensitive articles which do not have a mass explosive hazard. This division is comprised of articles which contain only extremely insensitive detonating substances and which demonstrate a negligible probability of accidental initiation or propagation.

Class 2: Gases

Subclass 2.1 - Flammable Gas

454 kg (1001 lbs) of any material which is a gas at 20°C (68°F) or less and 101.3 kPa (14.7 psi) of pressure (a material which has a boiling point of 20°C (68°F) or less at 101.3 kPa (14.7 psi)) which:

1. Is ignitable at 101.3 kPa (14.7 psi) when in a mixture of 13 percent or less by volume with air; or

2. Has a flammable range at 101.3 kPa (14.7 psi) with air of at least 12 percent regardless of the lower limit.

Subclass 2.2 - Non-flammable, Non-poisonus Gas

This division includes compressed gas, liquefied gas, pressurized cryogenic gas, compressed gas in solution, asphyxiant gas and oxidizing gas. A non-flammable, nonpoisonous compressed gas (Division 2.2) means any material (or mixture) which:

1. Exerts in the packaging an absolute pressure of 280 kPa (40.6 psia) or greater at 20°C (68°F), and

2. Does not meet the definition of Division 2.1 or 2.3.

Subclass 2.2 - Oxygen Gas

This is an optional placard to the 2.2 Non-flammable Gas placard for compressed Oxygen in either the gas or liquid state. Oxygen is considered a non-flammable because it in and of itself does not burn. It is, however, required for combustion to take place. High concentrations of oxygen greatly increases the rate and intensity of combustion.

Subclass 2.3 - Poison Gas

Gas poisonous by inhalation means a material which is a gas at 20°C or less and a pressure of 101.3 kPa (a material which has a boiling point of 20°C or less at 101.3kPa (14.7 psi)) and which:

1. is known to be so toxic to humans as to pose a hazard to health during transportation, or

2. in the absence f adequate data on human toxicity, is presumed to be toxic to humans because when tested on laboratory animals it has an LC50 value of not more than 5000 ml/m³.

Class 3: Flammable Liquids.

Flammable Liquid

A flammable liquid (Class 3) means a liquid having a flash point of not more than 60.5°C (141°F), or any material in a liquid phase with a flash point at or above 37.8°C (100°F) that is intentionally heated and offered for transportation or transported at or above its flash point in a bulk packaging, with the following exceptions:

1. Any liquid meeting one of the definitions specified in 49CFR 173.115.

2. Any mixture having one or more components with a flash point of 60.5°C (141°F) or higher, that make up at least 99 percent of the total volume of the mixture, if the mixture is not offered for transportation or transported at or above its flash point.

3. Any liquid with a flash point greater than 35°C (95°F) which does not sustain combustion according to ASTM 4206 or the procedure in Appendix H of this part.

4. Any liquid with a flash point greater than 35°C (95°F) and with a fire point greater than 100°C (212°F) according to ISO 2592.

5. Any liquid with a flash point greater than 35°C (95°F) which is in a water-miscible solution with a water content of more than 90 percent by mass.

Class 4: Flammable Solids or Substances

Class 4.1 - Flammable Solids or Substances

Desensitized explosives that when dry are explosives of Class 1 and are specifically authorized by name or have been assigned a shipping name and hazard class by the Associate Administrator.

Self-reactive materials,which are thermally unstable and that can undergo a strongly exothermic decomposition even without participation of air.

Readily combustible solids that can cause a fire through friction and show a burning rate faster than 2.2 mm (0.087 inches) per second, or metal powders that can be ignited and react over the whole length of a sample in 10 minutes or less.

Class 4.2 - Flammable solids

Spontaneously Combustible material is a pyrophoric material, which is a liquid or solid that can ignite within five (5) minutes after coming in contact with air or a self-heating material that when in contact with air and without an energy supply is liable to self-heat.

Class 4.3 - Substances which, in contact with water, emit flammable gases

Dangerous When Wet material is a material that when it makes contact with water is liable to become spontaneously flammable or give off flammable or toxic gas at a rate greater than 1 L per kilogram of the material per hour.

Class 5

Class 5.1 - Oxidizing substances (agents) by yielding oxygen increase the risk and intensity of fire

Oxidizer (Division 5.1) means a material that may, generally by yielding oxygen, cause or enhance the combustion of other materials.

1. A solid material is classed as a Division 5.1 material if, when tested in accordance with the UN Manual of Tests and Criteria, its mean burning time is less than or equal to the burning time of a 3:7 potassium bromate/cellulose mixture.

2. A liquid material is classed as a Division 5.1 material if, when tested in accordance with the UN Manual of Tests and Criteria, it spontaneously ignites or its mean time for a pressure rise from 690 kPa to 2070 kPa gauge is less then the time of a 1:1 nitric acid (65 percent)/cellulose mixture.

Class 5.2 - Organic peroxides - most will burn rapidly and are sensitive to impact or friction

Organic peroxide (Division 5.2) means any organic compound containing oxygen (O) in the bivalent -O-O- structure and which may be considered a derivative of hydrogen peroxide, where one or more of the hydrogen atoms have been replaced by organic radicals, unless any of the following paragraphs applies:

1. The material meets the definition of an explosive as prescribed in subpart C of this part, in which case it must be classed as an explosive;

2. The material is forbidden from being offered for transportation according to 49CFR 172.101 of this subchapter or 49CFR 173.21;

3. The Associate Administrator for Hazardous Materials Safety has determined that the material does not present a hazard which is associated with a Division 5.2 material; or

4. The material meets one of the following conditions:

1. For materials containing no more than 1.0 percent hydrogen peroxide, the available oxygen, as calculated using the equation in paragraph (a)(4)(ii) of this section, is not more than 1.0 percent, or

2. For materials containing more than 1.0 percent but not more than 7.0 percent hydrogen peroxide

Class 6

Class 6.1 - Toxic substances

Known to be toxic to humans so as to afford a hazard to health during transportation or is presumed to be toxic to humans because it falls within a toxic category when tested on laboratory animals.

An irritating material such as tear gas that causes extreme irritation, especially in confined spaces.

Class 6.2 - Infectious substances

Infectious Substance material is known to contain or suspected of containing a pathogen

3.6.2.1 Definitions

For the purposes of these Regulations:

3.6.2.1.1 Infectious substances are substances which are known or are reasonably expected to contain pathogens. Pathogens are defined as micro-organisms (including bacteria, viruses, rickettsiae, parasites, fungi) and other agents such as prions, which can cause disease in

humans or animals.

Note: Toxins from plant, animal or bacterial sources which do not contain any infectious substances or toxins that are not contained in substances which are infectious substances should be considered for classification in Division 6.1 and assigned to UN3172.

3.6.2.1.2 Biological products are those products derived from living organisms which are manufactured and distributed in accordance with the requirements of appropriate national authorities, which may have special licensing requirements, and are used either for prevention, treatment, or diagnosis of disease in humans or animals, or for development, experimental or investigational purposes related thereto. They include, but are not limited to, finished or unfinished products such as vaccines.

3.6.2.1.3 Cultures are the result of a process by which pathogens are intentionally. This definition does not include patient specimens as defined in 3.6.2.1.4.

3.6.2.1.4 Patient specimens are those collected directly from humans or animals, including, but not limited to, excreta, secreta, blood and its components, tissue and tissue fluid swabs, and body parts being transported for purposes such as research, diagnosis, investigational activities, disease treatment and prevention.

3.6.2.1.5 Medical or clinical wastes are wastes derived from the medical treatment of animals or humans or from bio-research.

3.6.2.2 Classification of Infectious Substances

3.6.2.2.1 Infectious substances must be classified in Division 6.2 and assigned to UN2814, UN2900, UN 3291 or UN3373, as appropriate.

3.6.2.2.2 Infectious substances are divided into the following categories.

3.6.2.2.2.1 Category A:

An infectious substance which is transported in a form that, when exposure to it occurs, is capable of causing permanent disability, life-threatening or fatal disease in otherwise healthy humans or animals. Indicative examples of substances that meet these criteria are given in Table 3.6.D.

Note: An exposure occurs when an infectious substance is released outside of the protective packaging, resulting in physical contact with humans or animals.

(a) Infectious substances meeting these criteria which cause disease in humans or both in humans and animals must be assigned to UN 2814. Infectious substances which cause disease only in animals must be assigned to UN 2900.

(b) Assignment to UN 2814 or UN 2900 must be based on the known medical history and symptoms of the source human or animal, endemic local conditions, or professional judgement concerning individual circumstances of the source human oranimal.

Notes:

1. The proper shipping name for UN 2814 is Infectious substance, affecting humans. The proper shipping name for UN 2900 is Infectious substance, affecting animals only.

2. The following table is not exhaustive. Infectious substances, including new or emerging pathogens, which do not appear in the table, but which meet the same criteria must be assigned to Category A. In addition, if there is doubt as to whether or not a substance meets the criteria it must be included in Category A.

3. In the following list, the micro-organisms written in italics are bacteria, mycoplasma, rickettsia or fungi.

Bacillus anthracis (cultures only)

Infectious substance

Brucella abortus (cultures only)

Brucella melitensis (cultures only)

Brucella suis (cultures only)

Burkholderia mallei – Pseudomonas mallei – Glanders (cultures only)

Burkholderia pseudomallei – Pseudomonas pseudomallei (cultures only)

Chlamydia psittaci – avian strains (cultures only)

Clostridium botulinum (cultures only)

Coccidioides immitis (cultures only)

Coxiella burnetii (cultures only)

Crimean-Congo hemorrhagic fever virus

Dengue virus (cultures only)

Eastern equine encephalitis virus (cultures only)

Escherichia coli, verotoxigenic (cultures only)

Ebola virus

Flexal virus

Francisella tularensis (cultures only)

Guanarito virus

Hantaan virus

Hantavirus causing hemorragic fever with renal syndrome

Hendra virus

Hepatitis B virus (cultures only)

Herpes B virus (cultures only)

Human immunodeficiency virus (cultures only)

Highly pathogenic avian influenza virus (cultures only)

Japanese Encephalitis virus (cultures only)

Junin virus

Kyasanur Forest disease virus

Lassa virus

Machupo virus

Marburg virus

Monkeypox virus

Mycobacterium tuberculosis (cultures only)

Nipah virus

Omsk hemorrhagic fever virus

Poliovirus (cultures only)

Rabies virus

Rickettsia prowazekii (cultures only)

Rickettsia rickettsii (cultures only)

Rift Valley fever virus

Russian spring-summer encephalitis virus (cultures only)

Sabia virus

Shigella dysenteriae type 1 (cultures only)

Tick-borne encephalitis virus (cultures only)

Variola virus

Venezuelan equine encephalitis virus

West Nile virus (cultures only)

Yellow fever virus (cultures only)

Yersinia pestis (cultures only)

African swine fever virus (cultures only)

Avian paramyxovirus Type 1 – Velogenic Newcastle disease virus (cultures only)

Classical swine fever virus (cultures only)

Foot and mouth disease virus (cultures only)

Goatpox virus (cultures only)

Lumpy skin disease virus (cultures only)

Mycoplasma mycoides – Contagious bovine pleuropneumonia(cultures only)

Peste des petits ruminants virus (cultures only)

Rinderpest virus (cultures only)

Sheep-pox virus (cultures only)

Swine vesicular disease virus (cultures only)

Vesicular stomatitis virus (cultures only)

3.6.2.2.2.2 Category B:

An infectious substance which does not meet the criteria for inclusion in Category A. Infectious substances in Category B must be assigned to UN 3373.

Note: The proper shipping name of UN 3373 is Diagnostic specimens or Clinical specimens or Biological substance, category B. On 1 January 2007, it is anticipated that the use of the shipping names Diagnostic specimens and Clinical specimens will no longer be permitted.

3.6.2.2.3 Exemptions

3.6.2.2.3.1 Substances which do not contain infectious substances or substances which are unlikely to cause disease in humans or animals are not subject to these Regulations unless they meet the criteria for inclusion in another class.

3.6.2.2.3.2 Substances containing microorganisms which are non-pathogenic to humans or animals are not subject to these Regulations unless they meet the criteria for inclusion in another class.

3.6.2.2.3.3 Substances in a form that any present pathogens have been neutralized or inactivated such that they no longer pose a health risk are not subject to these Regulations unless they meet the criteria for inclusion in another class.

3.6.2.2.3.4 Environmental samples (including food and water samples) which are not considered to pose a significant risk of infection are not subject to these Regulations unless they meet the criteria for inclusion in another class.

3.6.2.2.3.5 Dried blood spots, collected by applying a drop of blood onto absorbent material, or faecal occult blood screening tests and blood or blood components which have been collected for the purposes of transfusion or for the preparation of blood products to be used for transfusion or transplantation and any tissues or organs intended for use in transplantation are not subject to these Regulations.

3.6.2.2.3.6 Patient specimens for which there is minimal likelihood that pathogens are present are not subject to these Regulations if the specimen is packed in a packaging which will prevent any leakage and which is marked with the words "Exempt human specimen" or "Exempt animal specimen", as appropriate. The packaging must meet the following conditions:

(a) The packaging must consist of three components:

(i) a leak-proof primary receptacle(s);

(ii) a leak-proof secondary packaging; and

(iii) an outer packaging of adequate strength for its capacity, mass and intended use, and with at least one surface having minimum dimensions of 100 mm × 100 mm;

(b) For liquids, absorbent material in sufficient quantity to absorb the entire contents must be

placed between the primary receptacle(s) and the secondary packaging so that, during transport, any release or leak of a liquid substance will not reach the outer packaging and will not compromise the integrity of the cushioning material;

(c) When multiple fragile primary receptacles are placed in a single secondary packaging, they must be either individually wrapped or separated to prevent contact between them..

NOTE: In determining whether a patient specimen has a minimum likelihood that pathogens are present, an element of professional judgment is required to determine if a substance is exempt under this paragraph. That judgment should be based on the known medical history, symptoms and individual circumstances of the source, human or animal, and endemic local conditions.

Examples of specimens which may be transported under this paragraph include the blood or urine tests to monitor cholesterol levels, blood glucose levels, hormone levels, or prostate specific antigens (PSA); those required to monitor organ function such as heart, liver or kidney function for humans or animals with non-infectious diseases, or therapeutic drug monitoring; those conducted for insurance or employment purposes and are intended to determine the presence of drugs or alcohol; pregnancy test; biopsies to detect cancer; and antibody detection in humans or animals.

3.6.2.3 Biological Products

3.6.2.3.1 For the purposes of these Regulations, biological products are divided into the following groups:

(a) those which are manufactured and packaged in accordance with the requirements of appropriate national authorities and transported for the purposes of final packaging or distribution, and use for personal health care by medical professionals or individuals. Substances in this group are not subject to these Regulations

(b) those which do not fall under paragraph (a) and are known or reasonably believed to contain infectious substances and which meet the criteria for inclusion in Category A or Category B. Substances in this group must be assigned to UN2814, UN2900 or UN3373, as appropriate.

Note: Some licensed biological products may present a biohazard only in certain parts of the world. In that case, competent authorities may require these biological products to be in compliance with local requirements for infectious substances or may impose other restrictions.

3.6.2.4 Genetically Modified Micro-organisms and Organisms

3.6.2.4.1 Genetically modified micro-organisms not meeting the definition of an infectious substance must be classified according to Subsection 3.9.

3.6.2.5 Medical or Clinical Wastes

3.6.2.5.1 Medical or clinical wastes containing Category A infectious substances must be assigned to UN2814 or UN2900, as appropriate. Medical or clinical wastes containing infectious substances in Category B, must be assigned to UN3291.

3.6.2.5.2 Medical or clinical wastes which are reasonably believed to have a low probability of containing infectious substances must be assigned to UN3291. Note: The proper shipping name for UN3291 is Clinical waste, unspecified, n.o.s. or (Bio) Medical waste, n.o.s. or Regulated medical waste, n.o.s..

3.6.2.5.3 Decontaminated medical or clinical wastes which previously contained infectious substances are not subject to these Regulations unless they meet the criteria for inclusion in another class.

3.6.2.6 Infected Animals

3.6.2.6.1 A live animal that has been intentionally infected and is known or suspected to contain an infectious substance must not be transported by air unless the infectious substance contained cannot be consigned by any other means. Infected animals may only be transported under terms and conditions approved by the appropriate national authority.

3.6.2.6.2 Unless an infectious substance cannot be consigned by any other means, live animals must not be used to consign such a substance.

3.6.2.6.3 Animal carcasses affected by pathogens of category A or which would be assigned to category A in cultures only, must be assigned to UN 2814 or UN 2900 as appropriate. Other animal carcasses affected by pathogens included in Category B must be transported in accordance with provisions determined by the competent authority.

3.6.2.7 Patient Specimens Patient specimens must be assigned to UN 2814, UN 2900 or UN 3373 as appropriate except if they comply with 3.6.2.2.3

Class 7: Radioactive Substances

Class 7 - Radioactive Substances

Radioactives

Known to be toxic to humans so as to afford a hazard to health during transportation or is presumed to be toxic to humans because it falls within a toxic category when tested on laboratory animals.

Any quantity of packages bearing the RADIOACTIVE YELLOW III label (LSA-III). Some radioactive materials in "exclusive use" with low specific activity radioactive materials will not bear the label, however, the RADIOACTIVE placard is required.

Closed transport vehicle means a transport vehicle or conveyance equipped with a securely attached exterior enclosure that during normal transportation restricts the access of unauthorized persons to the cargo space containing the Class 7 (radioactive) materials. The enclosure may be either temporary or permanent, and in the case of packaged materials may be of the "see-through" type, and must limit access from top, sides, and bottom.

Containment system means the assembly of components of the packaging intended to retain the radioactive contents during transportation.

Conveyance means:

1. For transport by public highway or rail: any transport vehicle or large freight container;

2. For transport by water: any vessel, or any hold, compartment, or defined deck area of a vessel including any transport vehicle on board the vessel; and

3. For transport by aircraft, any aircraft.

Design means the description of a special form Class 7 (radioactive) material, a package, packaging, or LSA-III, that enables those items to be fully identified. The description may include specifications, engineering drawings, reports showing compliance with regulatory requirements, and other relevant documentation.

Exclusive use (also referred to in other regulations as "sole use" or "full load") means sole use by a single consignor of a conveyance for which all initial, intermediate, and final loading and unloading are carried out in accordance with the direction of the consignor or consignee. The consignor and the carrier must ensure that any loading or unloading is performed by personnel having radiological training and resources appropriate for safe handling of the consignment. The consignor must issue specific instructions in writing, for maintenance of exclusive use shipment controls, and include them with the shipping paper information provided to the carrier by the consignor.

Fissile material means plutonium-238, plutonium-239, plutonium-241, uranium-233, uranium-235, or any combination of these radionuclides. The definition does not apply to unirradiated natural uranium and depleted uranium, and natural uranium or depleted uranium that has been irradiated in a thermal reactor. Certain additional exceptions are provided in 49CFR 173.453.

Fissile material, controlled shipment means any shipment that contains one or more packages that have been assigned, in accordance with 49CFR 173.457, nuclear criticality control transport indices greater than 10.

Freight container means a reusable container having a volume of 1.81 cubic meters (64 cubic feet) or more, designed and constructed to permit its being lifted with its contents intact and intended primarily for containment of packages in unit form during transportation. A "small freight container" is one which has either one outer dimension less than 1.5 meters (4.9 feet) or an internal volume of not more than 3.0 cubic meters (106 cubic feet). All other freight containers are designated as "large freight containers."

Highway route controlled quantity means a quantity within a single package which exceeds:

1. 3,000 times the A1 value of the radionuclides as specified in 49CFR 173.435 for special form Class 7 (radioactive) material;

2. 3,000 times the A2 value of the radionuclides as specified in 49CFR 173.435 for normal form Class 7 (radioactive) material; or

3. 1,000 TBq (27,000 Ci), whichever is least.

Limited quantity of Class 7 (radioactive) material means a quantity of Class 7 (radioactive) material not exceeding the materials package limits specified in 49CFR 173.425 and conforming with requirements specified in 49CFR 173.421.

Low Specific Activity (LSA) material means Class 7 (radioactive) material with limited specific activity which satisfies the descriptions and limits set forth below. Shielding materials surrounding the LSA material may not be considered in determining the estimated average specific activity of the package contents.

Class 8: Corrosives

Class 8 - Corrosives

1. For the purpose of this subchapter "corrosive materials" (Class 8) means a liquid or solid that causes full thickness destruction of human skin at the site of contact within a specified period of time. A liquid that has a severe corrosion rate on steel or aluminum is also a corrosive material.

2. If human experience or other data indicate that the hazard of a material is greater or less than indicated by the results of the tests specified in paragraph (a) of this section, RSPA may revise its classification or make the determination that the material is not subject to the requirements of this subchapter.

3. Skin corrosion test data produced no later than September 30, 1995, using the procedures of 49CFR 173, Appendix A, in effect on September 30, 1995 (see 49CFR Part 173, Appendix A, revised as of October 1, 1994) for appropriate exposure times may be used for classification and assignment of packing group for Class 8 materials corrosive to skin.

454 kg (1001 lbs) or more gross weight of a corrosive material. Although the corrosive class includes both acids and bases, the hazardous materials load and segregation chart does not make any reference to the separation of various incompatible corrosive materials from each other. In spite of this, however, when shipping corrosives care should be taken to ensure that incompatible corrosive materials can not become mixed as many corrosives react very violently if mixed. If responding to a transportation incident involving corrosive materials (especially a mixture of corrosives), caution should be exercised.

Class 9: Miscellaneous dangerous substances and articles

Class 9 - Miscellaneous

A material which presents a hazard during transportation but which does not meet the definition of any other hazard class. This class includes:

1. Any material which has an anesthetic, noxious or other similar property which could cause extreme annoyance or discomfort to a flight crew member so as to prevent the correct performance of assigned duties; or

2. Any material for an elevated temperature material, a hazardous substance, a hazardous waste, or a marine pollutant.

Liner Terms:

The next main abbreviations are adopted in the commercial practice for line transportations between ports:

FIOS — Free in/out (loading/discharging is at consigner's cost)